ブロー成形・FLP

- ブロー成形

- 表皮一体

- 中空体

- インサート成形

- 大型成形

- 多層容器

- ガスバリア性

- 酸素バリア性

ブロー成形・FLPとは

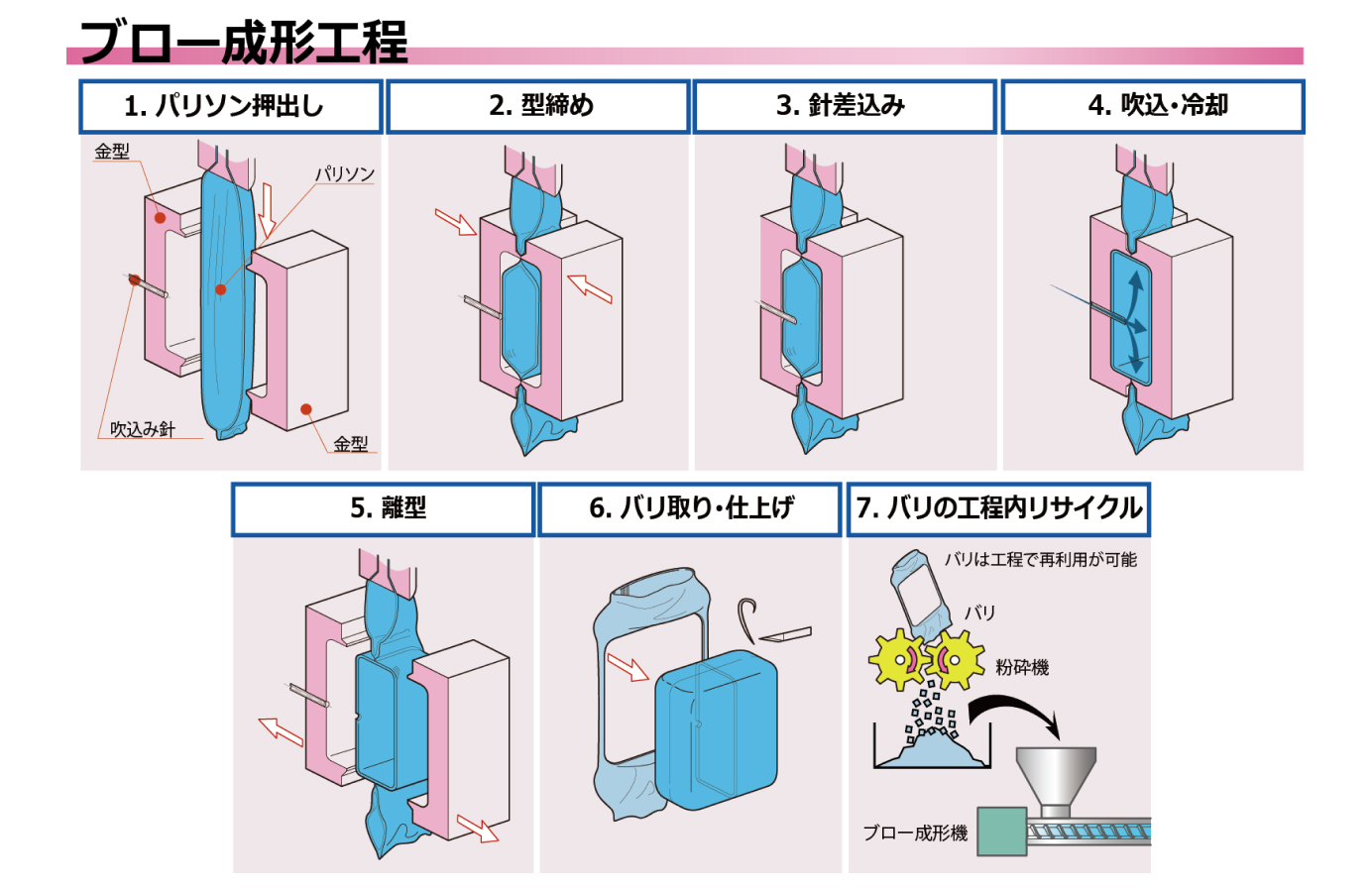

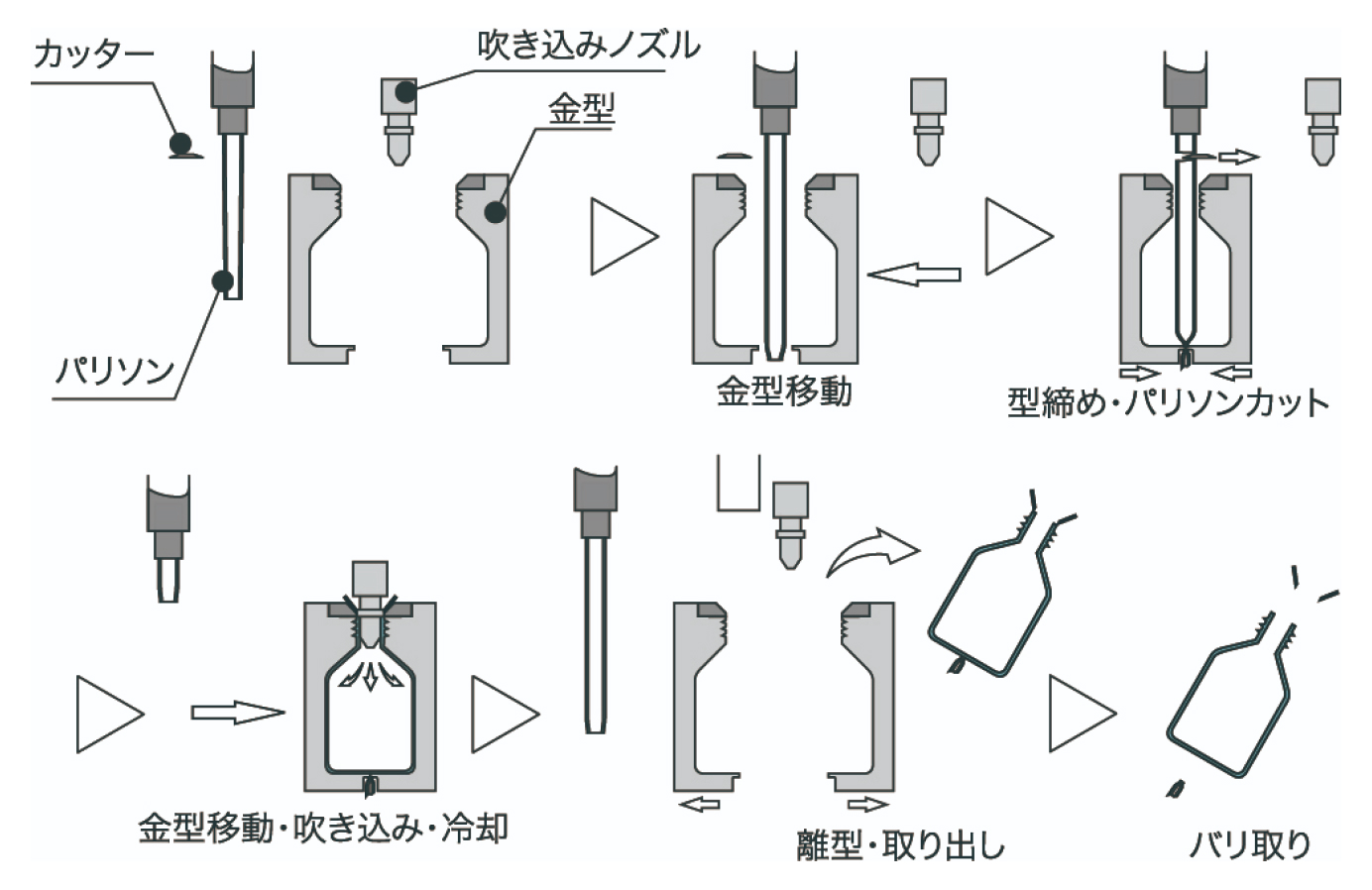

ブロー成形とは、プラスチックペレット(粒)を押出機によって溶融、混練、押出して、高温の金属筒(ヘッド)内を通過させ、筒状に溶融樹脂(パリソン)を成形します。そのパリソンを金型で挟み込み、針を挿入させ高圧の気体を吹き込みその圧力で金型内面にパリソンを押し付けた後に、冷却させて中空体を成形する方法です。

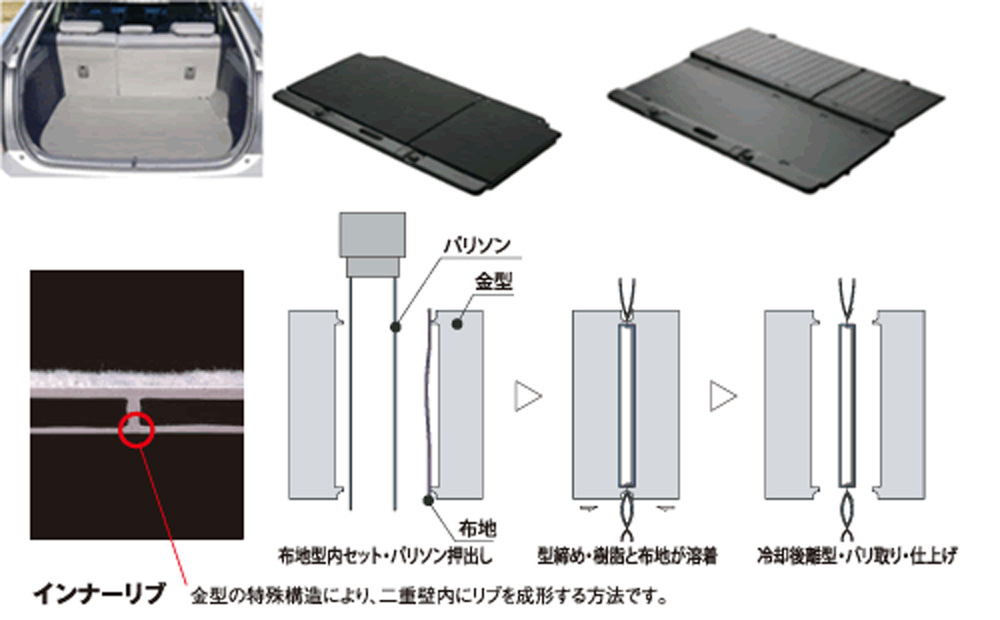

そのブロー成形技術に当社オリジナルのノウハウを取り入れる事で開発された成形方法がFLP(不織布一体成形:Fabric Laminated Plastics)という技術で、カーペットを接着剤不要で貼り付けられるので、低コストで環境にも優しい技術です。

ブロー成形・FLPのメリット

容器やタンクなどの中空体を成形するのに向いている

元々ガラス瓶の成形を基に開発された技術であり、膨らませた形状を作成するのが得意です。

中~小ロット生産向き

射出成形よりも一般的に金型費用が安価で生産数が少なくても対応できます

大型製品への対応が容易

大型成形に対して中空形状を活用する事で軽くて大きな製品にも対応できます

FLP技術でカーペットなどの表皮を一体で成形可能

ブロー成形と同時に型内で布地を製品に貼り付けるので、接着剤を使用せずに低コスト且つ環境負荷を抑えて一体化した製品が得られます。

技術紹介

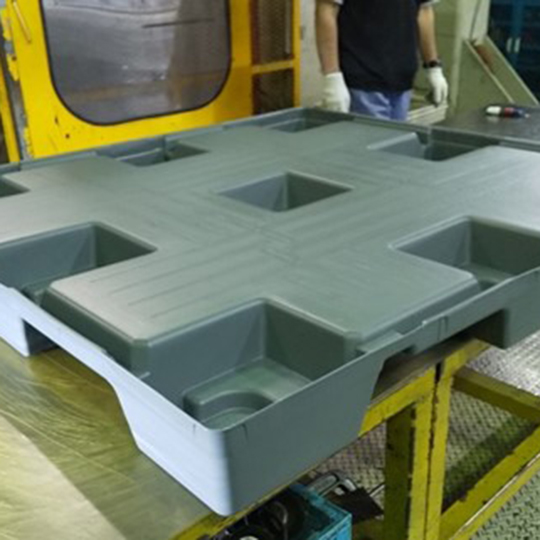

工業用ブロー成形

ブロー成形の中でも特に大きな製品を成形する際に、押出機からアキュームレータという部分に一時的に溶融した樹脂を貯めた後、油圧などの機構を使って一気に押し出して大きな製品を成形できます。最大で約50㎏(PE)まで樹脂を押し出すことが可能な成形機を所有しています。

製品例

シャトル式ブロー成形

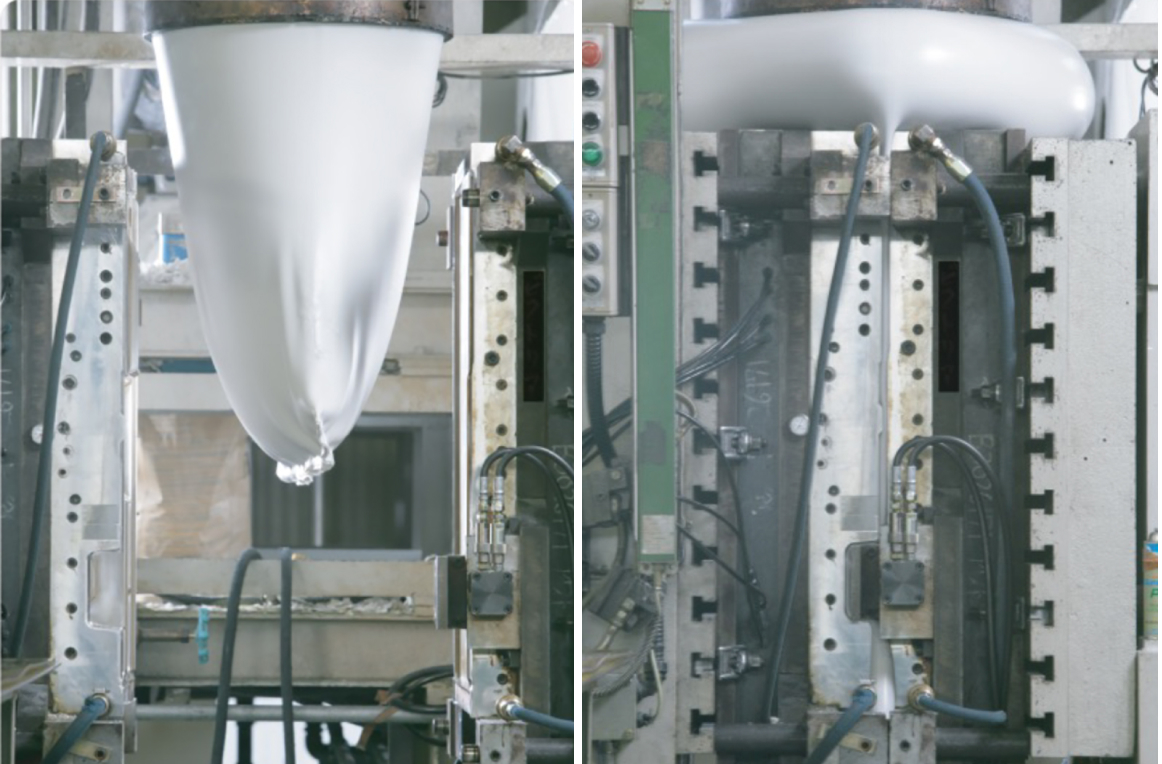

パリソンを連続して押出成形し、一定の長さに達した瞬間に金型で挟み込むと同時にパリソンをカットし、金型を吹き込み部まで移動させます。吹込み部にあるノズルをパリソン中空部へ挿入し、高圧の気体を吹き込み金型内面へ密着させ溶融樹脂を冷却し、中空体を成形する方法です。通常、上下に樹脂片(バリ)が発生するが、自動で分離できるようになっている。左右に金型移動を繰り返すため、シャトル式ブロー成形機と呼ばれます。

製品例

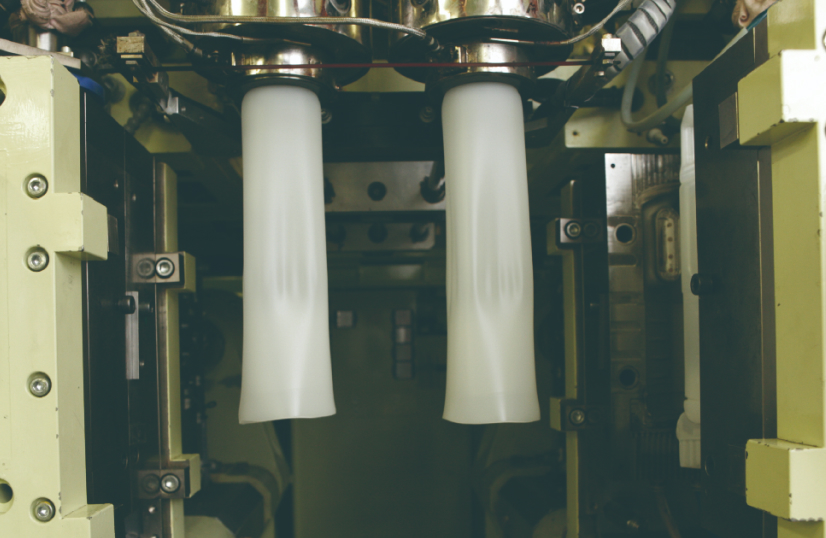

ロータリー式ブロー成形

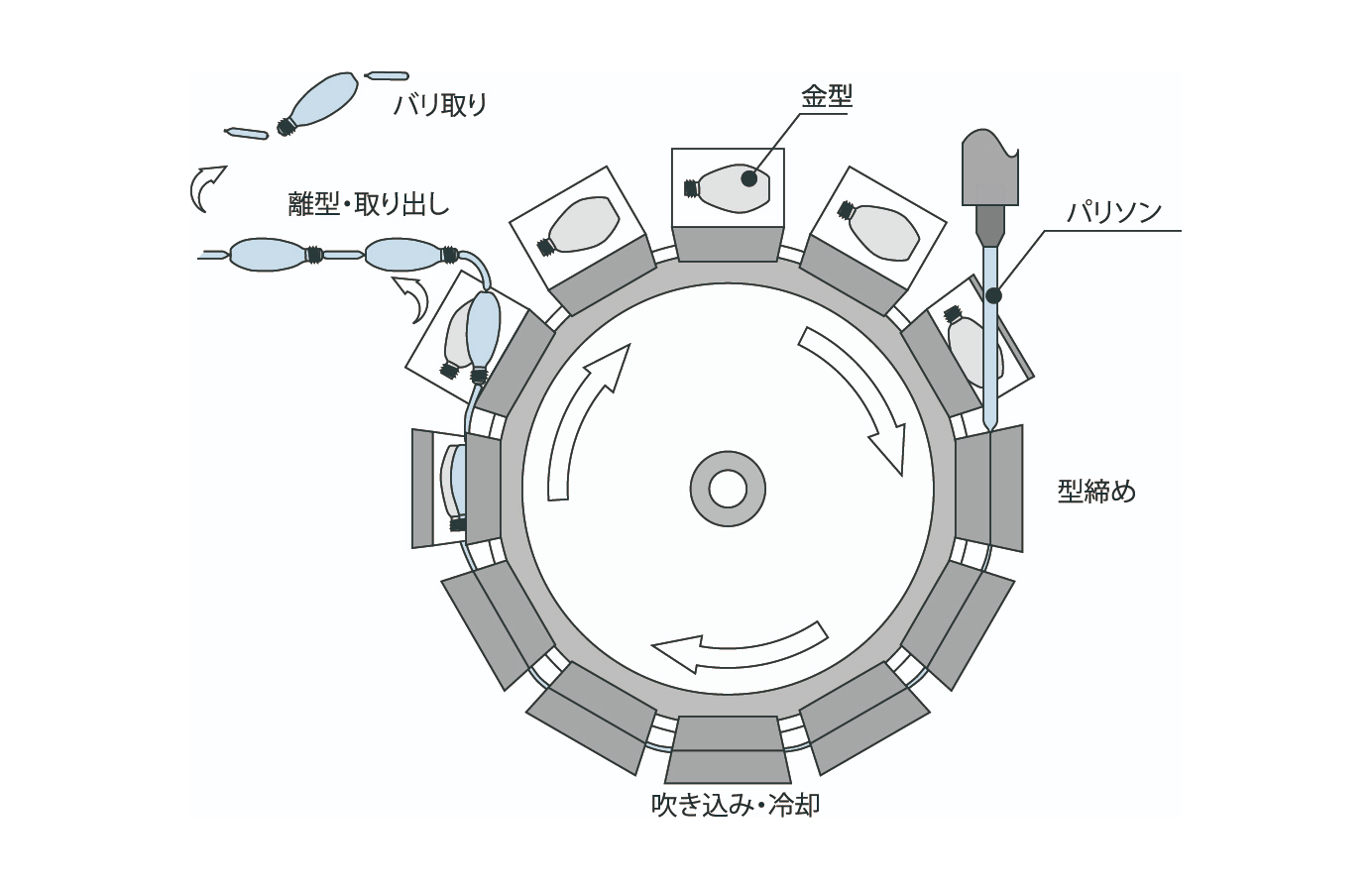

円盤上に金型を十数型設置し、型開き型締めを連続的に実施させ、パリソンを挟み込み型締めと同時に針をパリソン内に挿入し、高圧気体を吹き込みます。気体圧力で金型内面にパリソンを密着させ溶融樹脂を冷却し、中空製品を形成する。金型を連続的に回転させながら成形するため、ロータリー式ブロー成形機と呼ばれます。

製品例

FLP(不織布一体成形)

FLP(不織布一体成形:Fabric Laminated Plastic)とは、ブロー成形技術を応用して、金型内にあらかじめ布地をセットしておき、ブロー成形と同時に型内で布地を製品に貼り付けます。接着剤を使用せずに、低コスト且つ環境負荷を抑えて、製品表面に布地を貼れます。また、布地と製品の材質を同じにすれば一緒にリサイクル可能なため、さらに環境への負担も小さくなります。

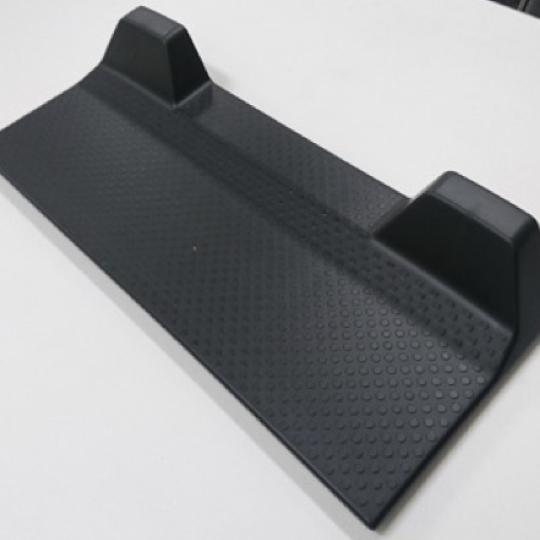

製品例

こんなお悩みはありませんか?

- アイデアはあるが、どう実現したら良いかわからない…

- プラスチック製品の知識も、ノウハウもない…

- どこで作れる?

当社は長年培ってきたブロー成形を得意としておりますが、さらに当社オリジナルのノウハウを取り入れくことにより、さらに発展させた新たな成形方法/製品開発に取り組んでおります。

また、他のプラスチック成形方法である射出成形、押出成形、真空圧空成形などにも知見、経験があります。

プラスチック製品についても自動車部品、一般成形品、食品・医療容器、フィルム等、幅広く取り扱っている為、プラスチックによる物づくりに関するご相談もお受けすることが出来ます。

当社はプラスチックの総合企業として、製品の設計はもちろん、開発・量産までの全工程を当社の設備とスタッフが行い、お客さまのものづくりをトータルにサポート致します。