TBM・FLP Lite・FLP Lite CL

- TBM

- 表皮一体

- インサート成形

- サンドイッチ構造

- 軽量化

- 高剛性

- 断熱性

- 表裏異材質

TBM(ツインブロー製法)

FLP Lite・FLP Lite CLとは

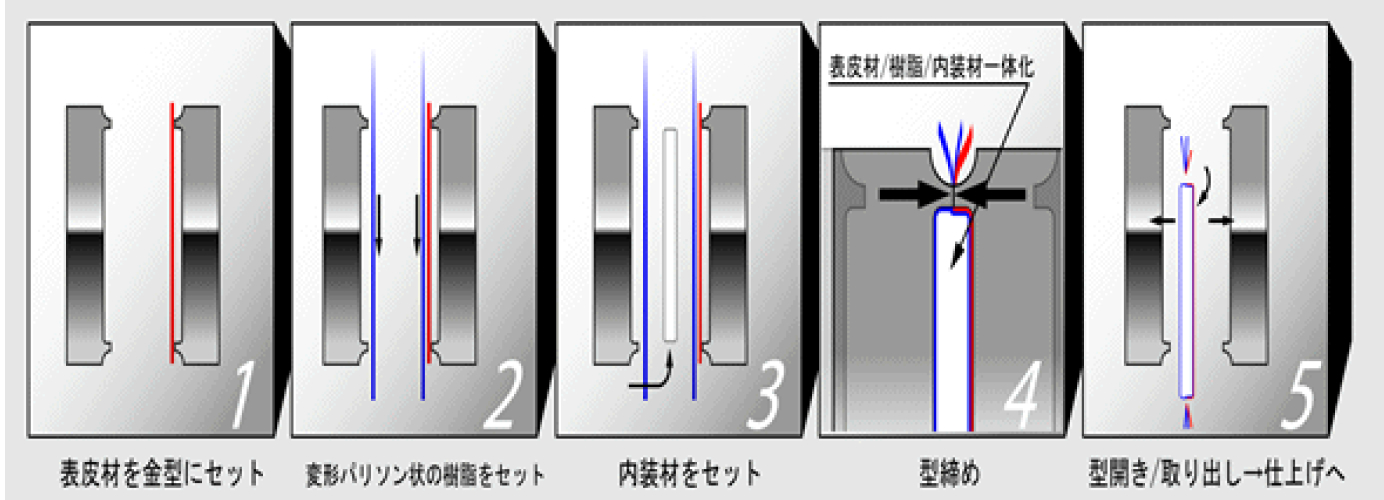

TBM製法は変形パリソンを用いることで、従来のブロー成形では困難であった下記のような特長を持つ製品が得られます。さらに、当社オリジナルであるFLP技術と組み合わせたFLP Lite、FLP Lite CLなど幅広いラインナップにより、お客様のアイデアに沿った多様な製品をご提供いたします。

TBM・FLP Lite・FLP Lite CLのメリット

発泡体などの内装材インサート

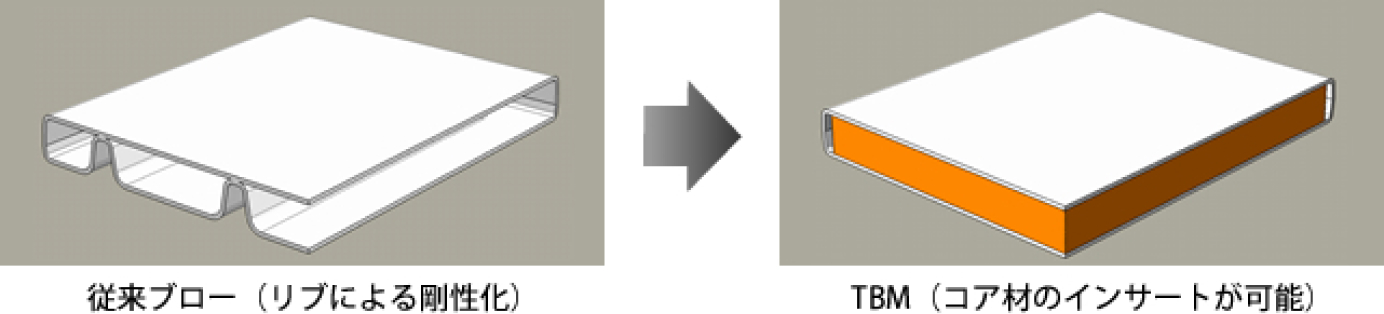

補強リブ構造に比べて軽量、且つ剛性のあるサンドイッチ構造にすることで強度アップを図れます。

また、補強リブが必要なくことで、両面フラットな意匠にすることができます。さらに、中空部に断熱材を入れることにより、断熱性能を持たせるなど、内装材による機能を付加できます。

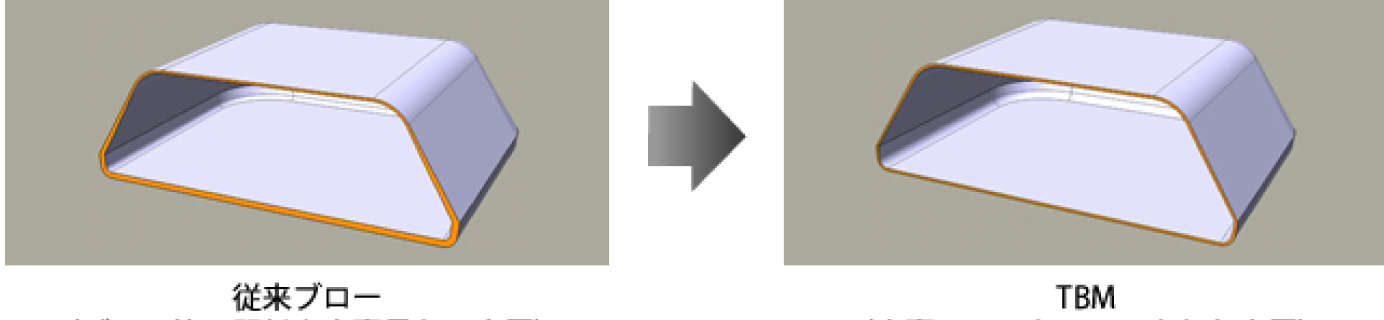

表裏でコントロールされた肉厚(軽量化)

表裏でブロー比が大きく違う場合においても肉厚差を小さくすることが出来ます。

上記により、パーティングライン設定の自由度が向上します。

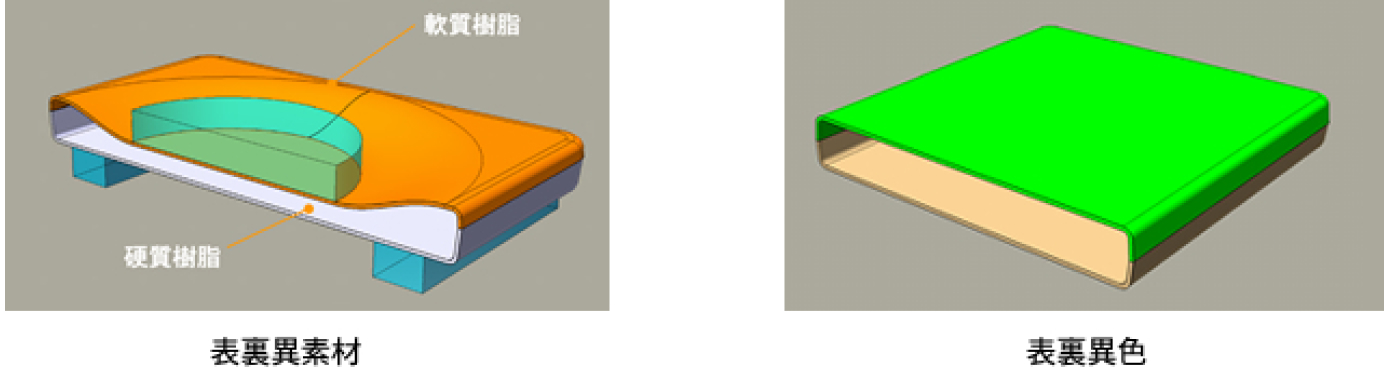

表裏で異色・異材の使用

表裏異材質にて成形が可能です。(例:表面軟質材料/裏面硬質材料、表面バージン材/裏面リサイクル材など)

また、表裏異色にて成形も可能です。(塗装などが不要になります)

TBM製法とFLP技術を組み合わせた、カーペットなどの表皮を一体で成形可能

当社が開発したTBM製法と従来のFLP技術を組み合わせて、より軽量、且つ高剛性で新しい特長のある、表皮などを一体化した製品のご提供も可能です。

技術紹介

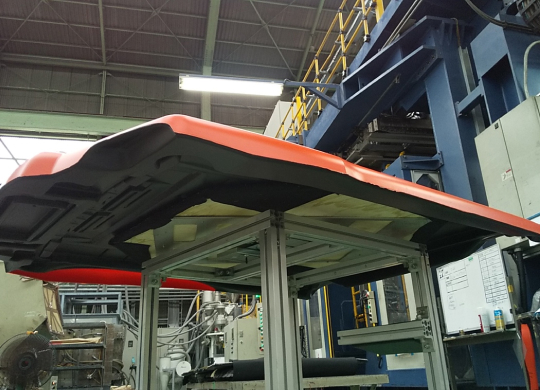

TBM

TBM製法は変形パリソンを用いることで、従来のブロー成形では困難であった

- 発泡体などの内装材インサート

- 表裏コントロールされた肉厚

- 表裏で異色・異材の使用

などが可能であり、ブロー成形よりも軽量で新しい製品の提供をご提供できます。

製品例

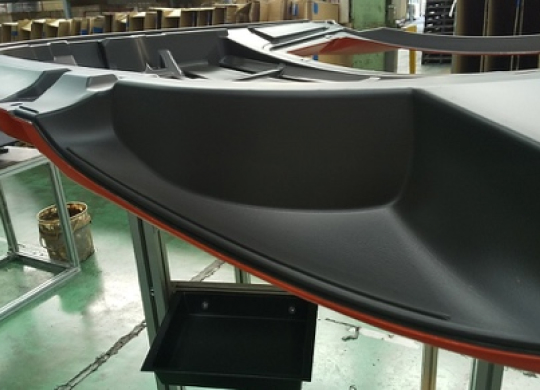

FLP Lite

FLP Lite製法は上記TBMと当社がこれまでに培ってきたFLP(不織布一体成形)技術を組み合わせることで、従来FLP(不織布一体成形)では困難であった

- 発泡体などの内装材インサート

- 表裏コントロールされた肉厚

- 表裏で異色・異材の使用

- 裏面のフラット化

などが可能であり、FLPよりも軽量、且つ高剛性で新しい特長のある製品をご提供できます。

製品例

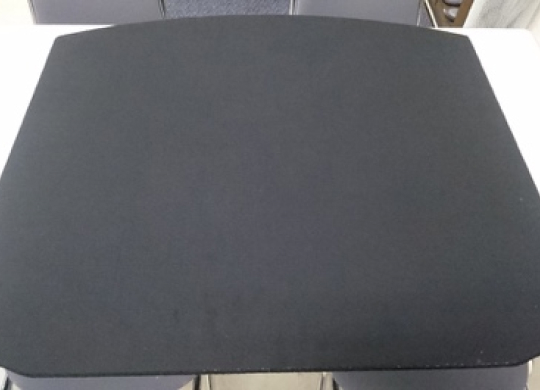

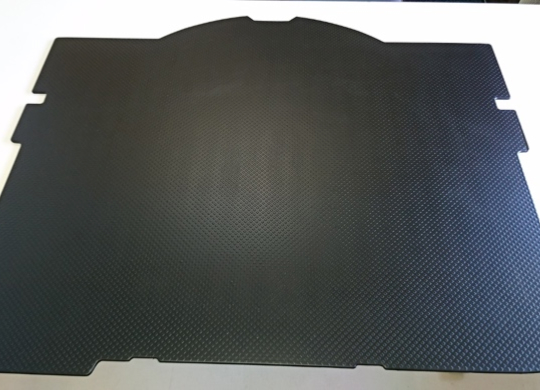

FLP Lite CL

FLP Lite CL製法は変形パリソンを用いることで従来のブロー工法では困難であった薄肉化を実現しました。FLP Liteとは異なり、内装材のインサートは採用せず、

- ヒンジ一体成形

- 3D成形

- 小部品インサート(アルミ押出材はアウトサート)

などが可能であり、従来のFLPよりも軽量で新しい特長のある製品をご提供できます。

製品例

こんなお悩みはありませんか?

- アイデアはあるが、どう実現したら良いかわからない…

- プラスチック製品の知識も、ノウハウもない…

- どこで作れる?

当社は長年培ってきたブロー成形を得意としておりますが、さらに当社オリジナルのノウハウを取り入れくことにより、さらに発展させた新たな成形方法/製品開発に取り組んでおります。

また、他のプラスチック成形方法である射出成形、押出成形、真空圧空成形などにも知見、経験があります。

プラスチック製品についても自動車部品、一般成形品、食品・医療容器、フィルム等、幅広く取り扱っている為、プラスチックによる物づくりに関するご相談もお受けすることが出来ます。

当社はプラスチックの総合企業として、製品の設計はもちろん、開発・量産までの全工程を当社の設備とスタッフが行い、お客さまのものづくりをトータルにサポート致します。