Features of Kyoraku

As a pioneer of plastics, we respond to various needs and solve problems with our long history, accumulated experience and knowledge across multiple fields, and advanced technological capabilities backed by patents.

We have been providing plastic products to customers in many fields and industries for more than 70 years, and our achievements and know-how are our great assets.

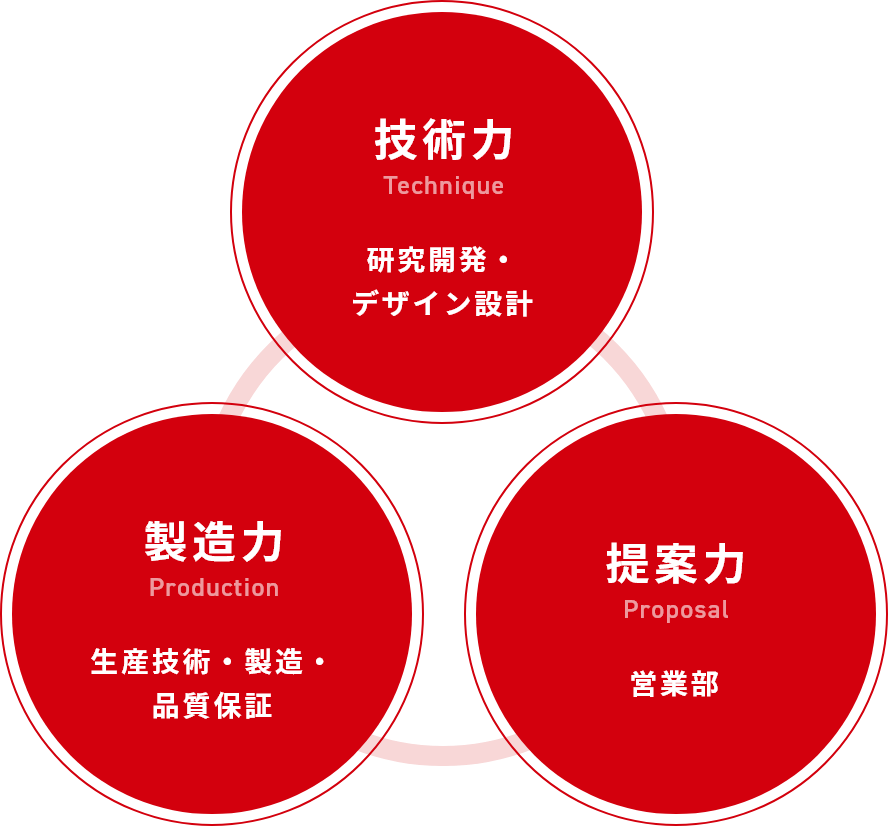

"R&D/Design", "Production Technology/Manufacturing", "Sales", and "Management/Business" that supports them are integrated, and we have a system that can provide solutions to customer's problems and needs through a planning and proposal type approach. I have.

This system is a major feature and strength that has supported Kyoraku's growth.

We will continue to create environmentally friendly products that are friendly to people and society, and to meet the diverse needs of society.

01

High technology of blow molding and numerous patented technologies

We have acquired more than 1,000 patents in Japan and overseas (approximately 1,400 as of August 2022), mainly for blow molding technology.

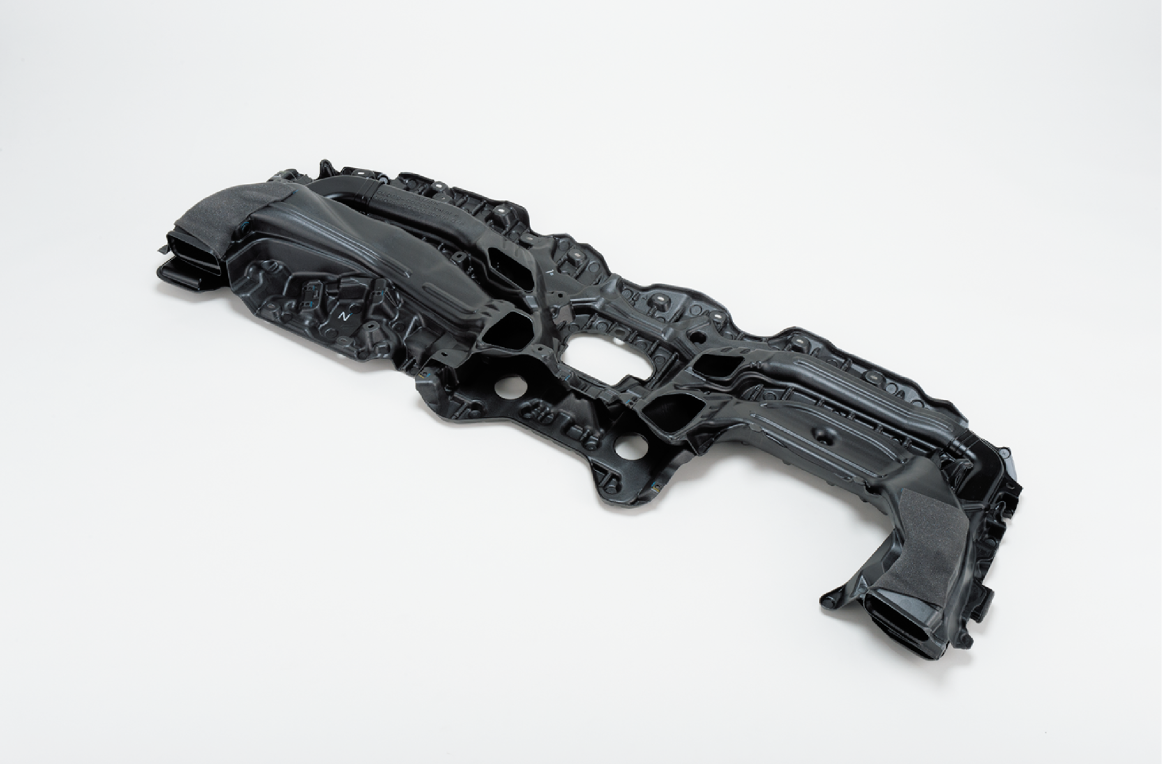

Products realized by Kyoraku's patented technology include Foamed Duct (automobile parts), Fresh Sqeeze Bottle (food containers), Microwave Oven Bags (food packaging materials), and floats for water solar power generation (mounts), etc., and the convenience of the products. Contributes to improvement and efficiency.

In addition, we have acquired a patent for our unique molding technology "TBM", which is an evolution of blow molding technology, which contributes to the weight reduction of luggage compartment boards for automobiles. These advanced technologies are created through collaboration and constant challenge among departments such as the R&D Department, Design Department, Production Technology Department, and Manufacturing Department, as well as collaboration with the Sales Department, which meets customer needs.

Learn more about "TBM", an evolutionary system of blow molding

Products born from original technology

02

R&D system

As the core of new technology development, the research and development department is working on new technology development in close cooperation with each business office and manufacturing plant based on blow molding technology cultivated over many years. The target of development is not limited to blow molding, and the target products are wide-ranging, including automobile parts, food containers, and medical precision parts.

These extensive development systems and the ability to apply technology across fields have led to the long-term trust of automobile manufacturers and food manufacturers.

03

Design support system

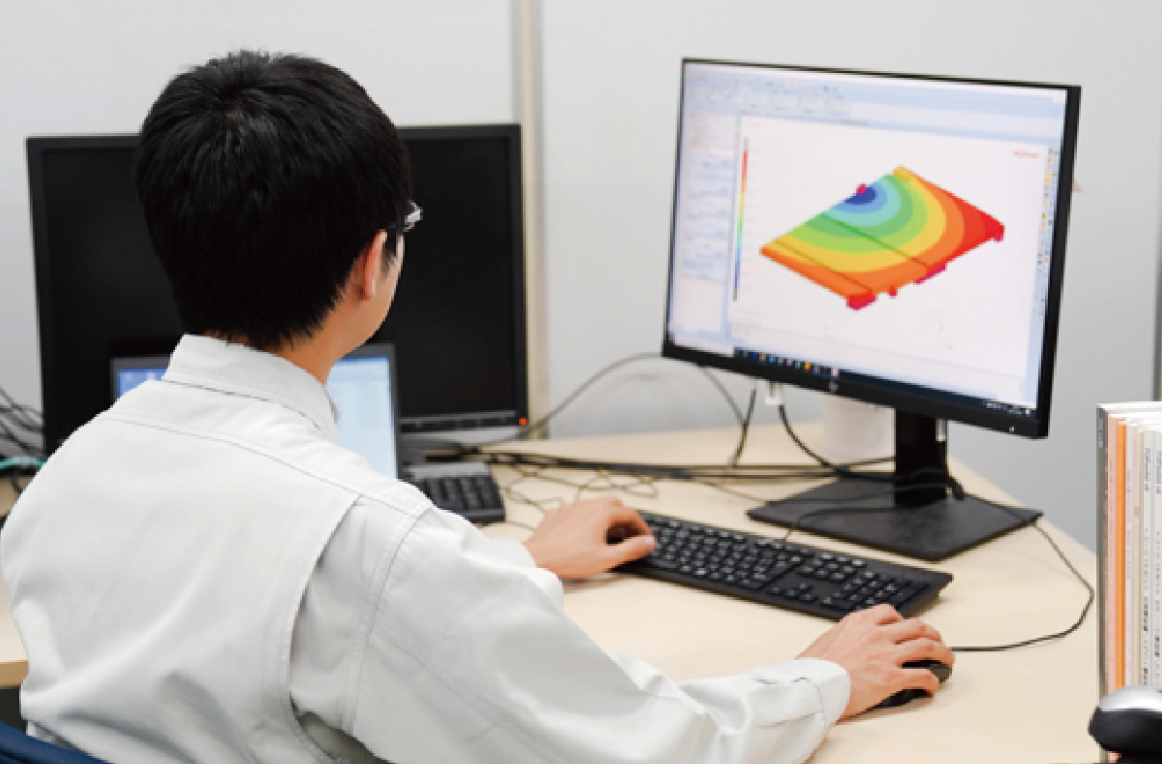

Experienced personnel in plastic molding, including blow molding, use 3D CAD to propose product shapes suitable for mass production.

We also carry out preliminary design verification through CAE simulations during use and molding, and model creation through rapid prototyping. We are also involved in prototyping and evaluation after mold production, and support throughout the entire process up to product mass production.

04

“High-quality products” and “production and supply capabilities” that meet the needs of society

We promote the introduction and development of automation and labor-saving technologies for the manufacturing process, build a more efficient mass production system, and have our own factories in Ibaraki in the Kanto region, Gifu and Aichi in the Chubu region, and Shiga in the Kansai region. is manufacturing. We have also established a quality assurance system to ensure that we continue to deliver products of the quality promised to our customers.

In addition, we not only introduce Blow Molding Machine packed with know-how accumulated as a blow molding manufacturer into our factories, but also sell them to outside parties. Based on our track record of mass-production molding for a wide variety of products, we can propose molding machines with optimal specifications for products that customers want to make, and provide technical follow-up such as the start-up of mass production.

05

High ability to make proposals and solve problems as a team

Our sales team listens carefully to the voices of our customers, makes full use of various departments and functions within the company, and proposes and introduces the best technology for your requests and needs as a team.

In addition, we manage the entire product development project and promote product realization.

Furthermore, we not only respond to the needs of customers who have clear specific requirements, but also design and visualize their vague ideas of "I want to make something like this" by getting into their pockets. , we also help shape it into a product.

By all means, we can respond and propose to a wide range of fields such as food containers, packaging materials, medical / nursing care, automobile parts, housing materials and logistics materials, and we can also manufacture and sell the molding machines themselves for making parts. Please contact us with your expectations for the unique features and strengths of Kyoraku.