Extrusion

- Extrusion

- profile extrusion

- multilayer extrusion

- Gas barrier property

- Oxygen barrier

- long product molding

What is extrusion

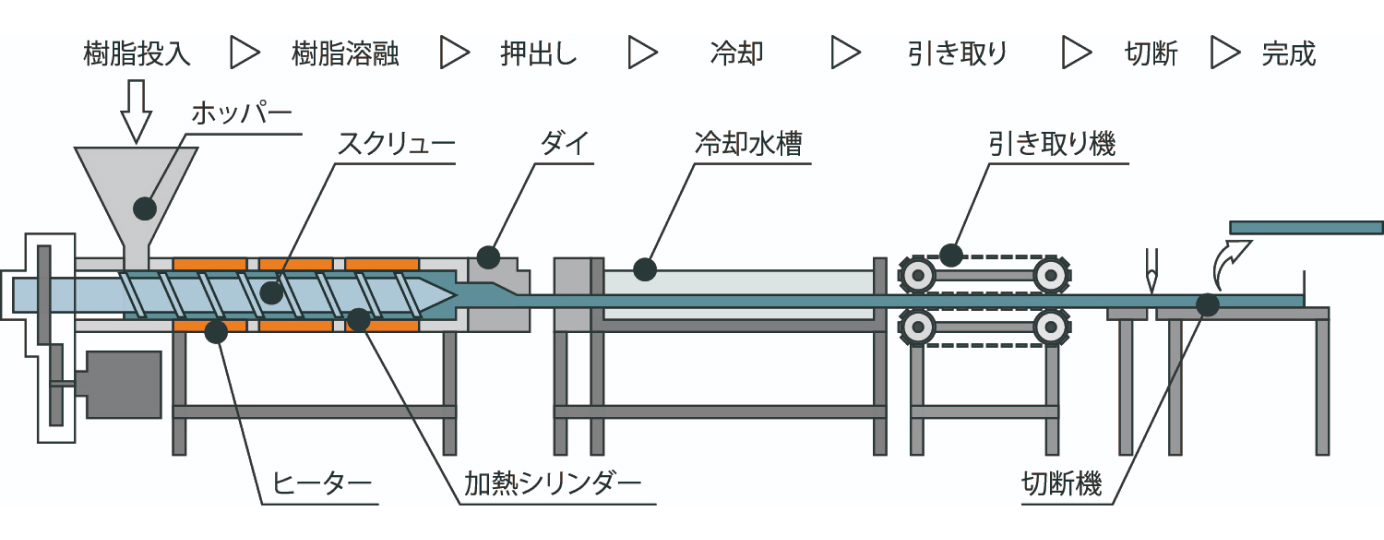

This is a molding method in which resin pellets supplied from a hopper are melted in a heating cylinder, kneaded with a screw, and extruded to continuously form moldings with a constant cross-sectional shape.

Advantages of extrusion

Production of fixed cross-section products

Products with a constant cross-sectional shape can be produced stably and continuously.

Laminate molding with different resins is possible

It is possible to extrude in a form in which different resins are layered, and it is also possible to add functions such as gas barrier properties to tubes.

Technology introduction

Extrusion

The resin pellets supplied from the hopper are melted in the heating cylinder, kneaded with a screw, and extruded to send the plasticized resin to the tip of the cylinder. After that, by extruding the resin according to the shape of the mold attached to the tip of the cylinder, it is a technology to continuously mold the product with the shape of the cross section. In many cases, it is then cut to the required length and used as a product.

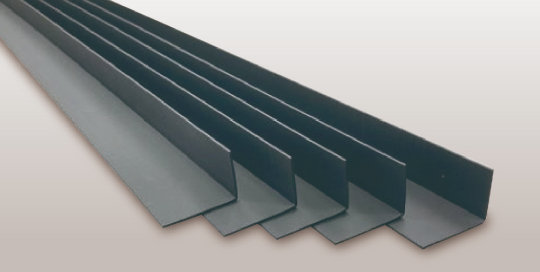

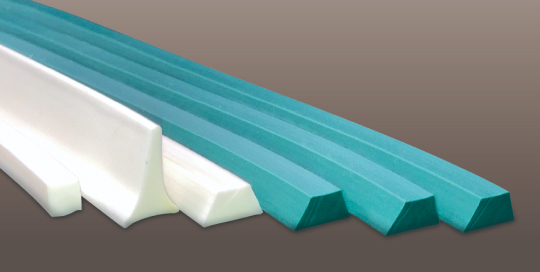

Product examples

Do you have anyworriesorconcerns ?

- I have an idea, but I don't know how to implement it...

- I don't have knowledge or expertise in plastic products...

- Where can i make it

Our company specializes in blow molding, which we have cultivated over many years, and we are working on further developing new molding methods and product development by incorporating our original know-how.

We also have knowledge and experience in other plastic molding methods such as injection molding, extrusion molding, and vacuum pressure molding.

We also handle a wide range of plastic products, such as automobile parts, general molded products, food and medical containers, and films, so we can also accept consultations on manufacturing with plastic.

As a comprehensive plastics company, we provide total support for the manufacturing of our customers by using our facilities and staff to handle all processes from product design to development and mass production.

Inquiries/Consultation

Inquiries/Consultation

For inquiries and consultations

From the form below,

Please feel free to contact us.

We can also meet online.