Foamed Blow Molding

- Foamed Blow Molding

- Weight saving

- Thermal insulation properties

- sound insulation

- low environmental impact

What is Foamed Blow Molding

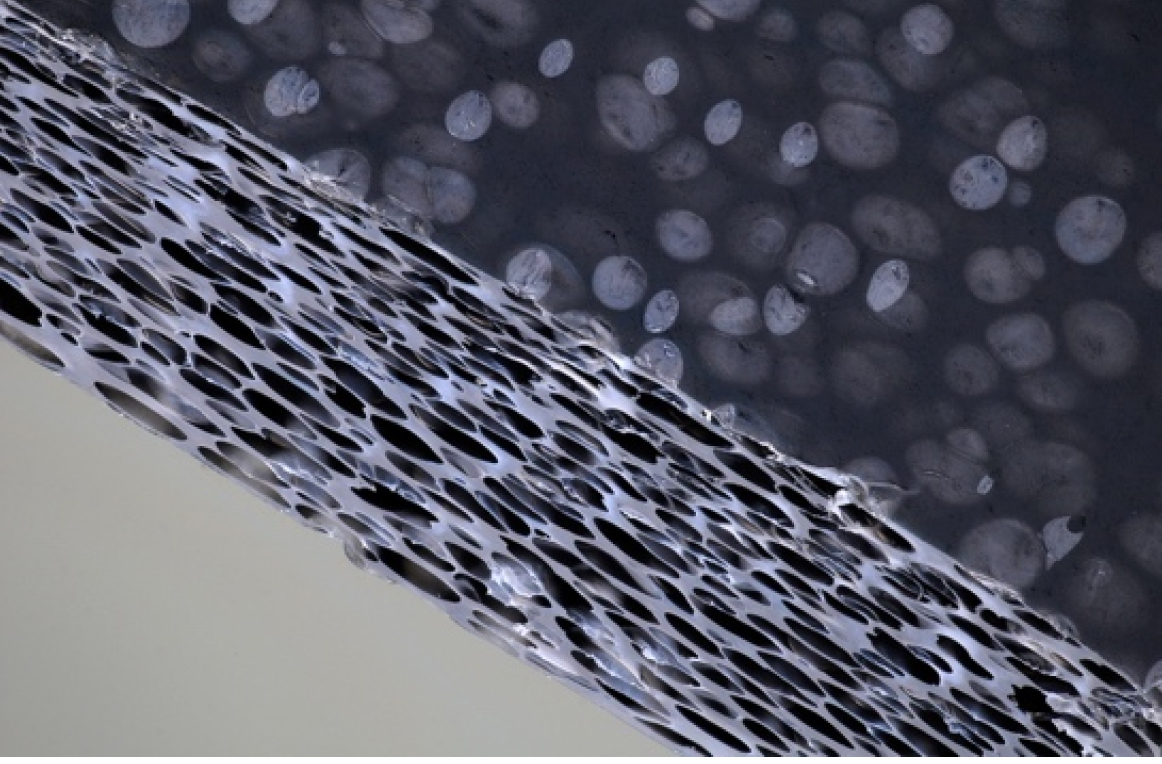

With our advanced Foamed Blow Molding technology, we are able to provide low-cost, low-environmental-impact products that are ultra-lightweight, highly heat-insulating, sound-insulating, cost-reduced by not requiring heat-insulating urethane coating, and excellent recyclability. We propose the optimal combination of foaming ratio, product thickness, and materials to meet the diverse needs of our customers.

Advantages of Foamed Blow Molding

Super lightweight

By composing the product with foamed material, the product itself can be greatly reduced in weight.

High thermal insulation

Composing a product with foamed material greatly improves thermal insulation performance. In addition, it contributes to the reduction of heat insulation packing that was pasted on conventional ducts.

Technology introduction

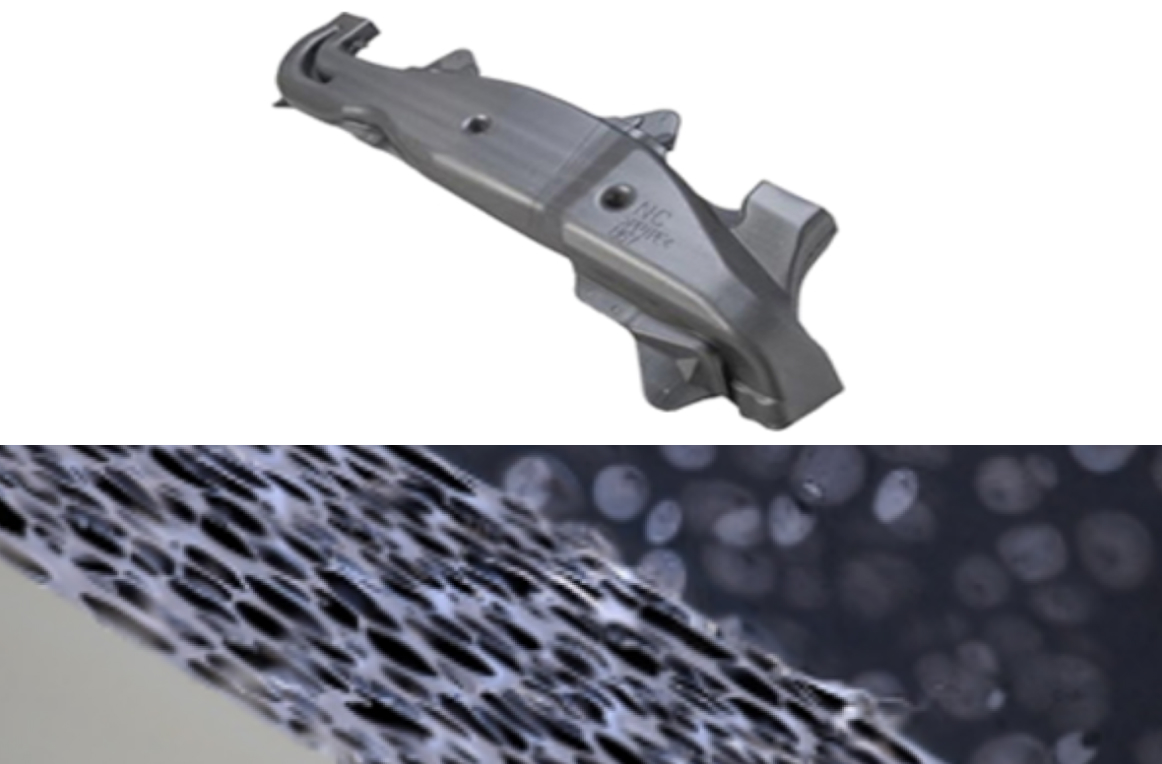

Foamed Blow Molding

Combining conventional blow molding technology with our unique manufacturing know-how, we propose highly foamed products through physical foaming by Foamed Blow Molding, and provide products that meet customer needs.

Product examples

Do you have anyworriesorconcerns ?

- I have an idea, but I don't know how to implement it...

- I don't have knowledge or expertise in plastic products...

- Where can i make it

Our company specializes in blow molding, which we have cultivated over many years, and we are working on further developing new molding methods and product development by incorporating our original know-how.

We also have knowledge and experience in other plastic molding methods such as injection molding, extrusion molding, and vacuum pressure molding.

We also handle a wide range of plastic products, such as automobile parts, general molded products, food and medical containers, and films, so we can also accept consultations on manufacturing with plastic.

As a comprehensive plastics company, we provide total support for the manufacturing of our customers by using our facilities and staff to handle all processes from product design to development and mass production.

Inquiries/Consultation

Inquiries/Consultation

For inquiries and consultations

From the form below,

Please feel free to contact us.

We can also meet online.