TBM・FLP Lite・FLP Lite CL

- TBM

- Epidermis

- Insert molding

- sandwich structure

- Weight saving

- high rigidity

- Thermal insulation properties

- Different materials on front and back

TBM (twin blow manufacturing method)

What is FLP Lite and FLP Lite CL?

By using deformed parison in the TBM manufacturing method, it is possible to obtain products with the following features that were difficult with conventional blow molding. In addition, we offer a wide range of products that meet the ideas of our customers, such as FLP Lite and FLP Lite CL, which are combined with our original FLP technology.

Advantages of TBM/FLP Lite/FLP Lite CL

Interior material inserts such as foam

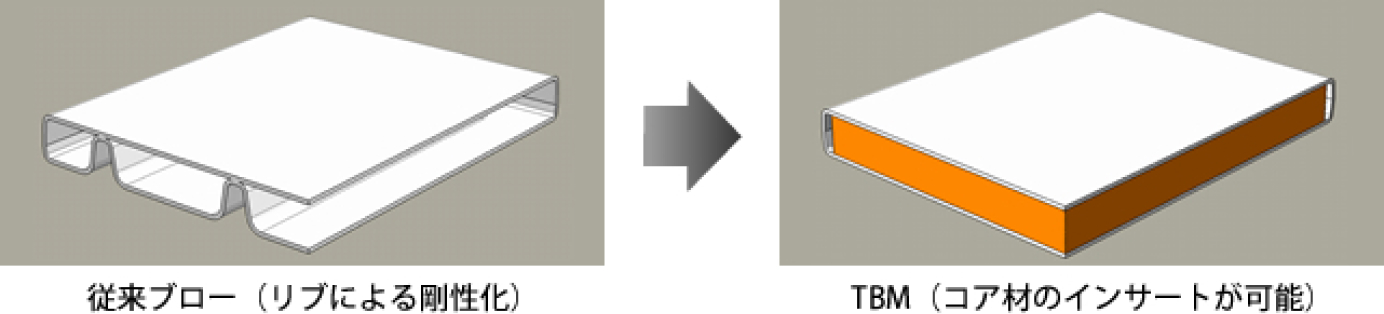

Compared to the reinforcing rib structure, the strength can be increased by adopting a sandwich structure that is lighter and more rigid.

In addition, by eliminating the need for reinforcing ribs, it is possible to achieve a flat design on both sides. Furthermore, by inserting heat insulating material into the hollow part, it is possible to add functions by the interior material, such as providing heat insulation performance.

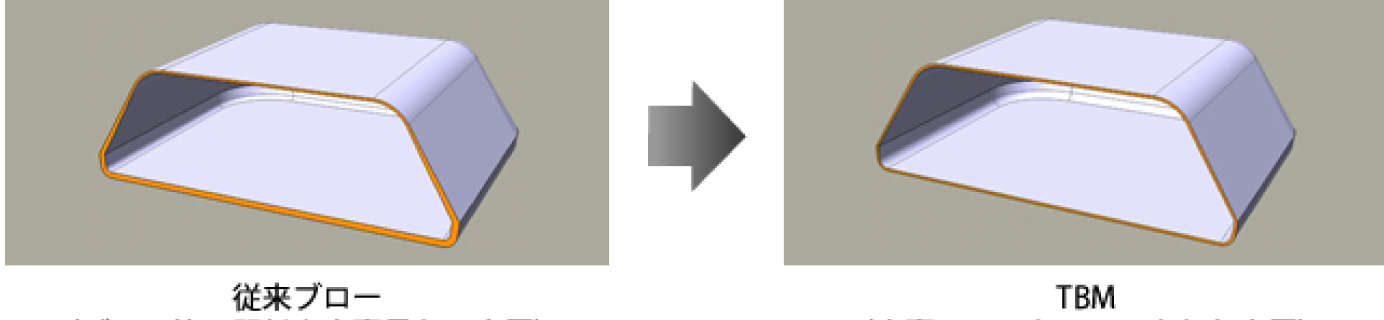

Wall thickness controlled on the front and back (lightening)

Even if the blow ratio is greatly different between the front and back, the wall thickness difference can be reduced.

The above increases the degree of freedom in setting the parting line.

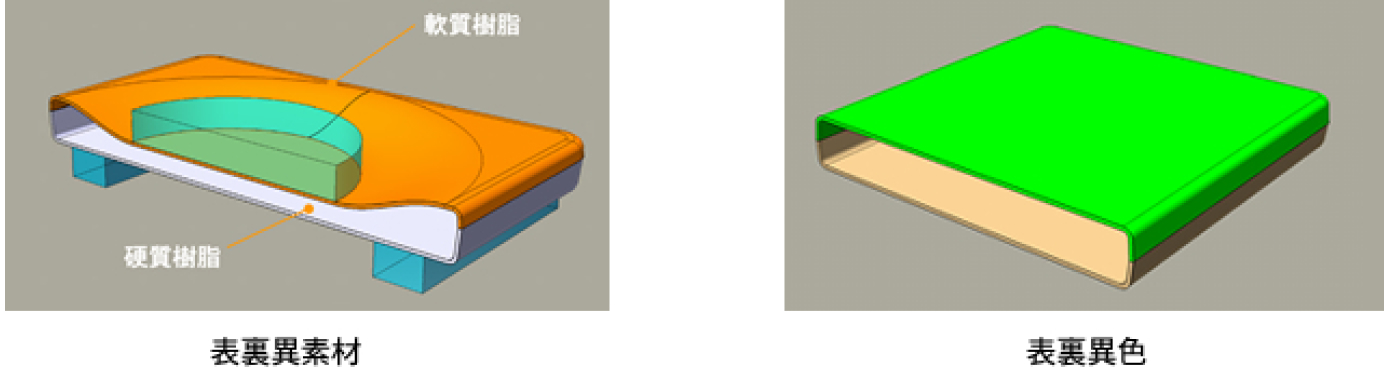

Use of different colors and different materials on the front and back

Molding is possible with different materials on the front and back. (Example: soft surface material/hard back material, virgin surface material/recycled back material, etc.)

It is also possible to mold with different colors on the front and back. (No need for painting etc.)

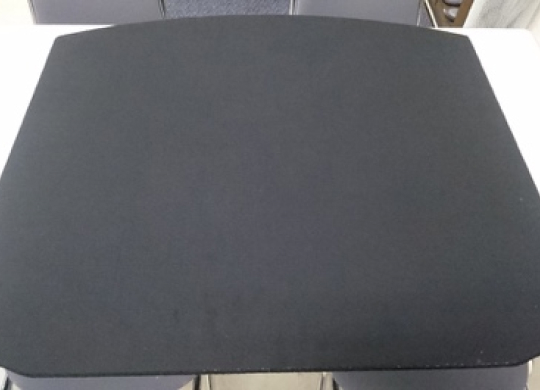

Combining the TBM manufacturing method and FLP technology, it is possible to integrally mold the skin of carpets, etc.

By combining the TBM manufacturing method developed by our company with conventional FLP technology, it is also possible to provide products that are lighter, have higher rigidity, and have new features, such as an integrated skin.

Technology introduction

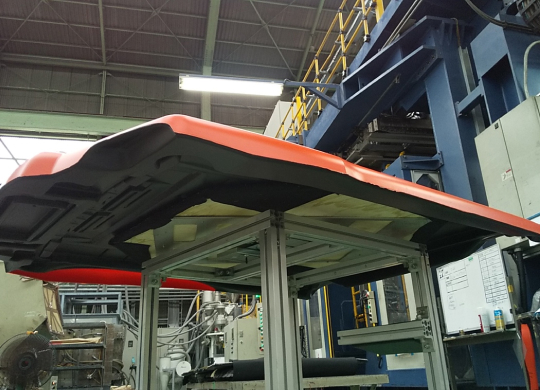

TBM

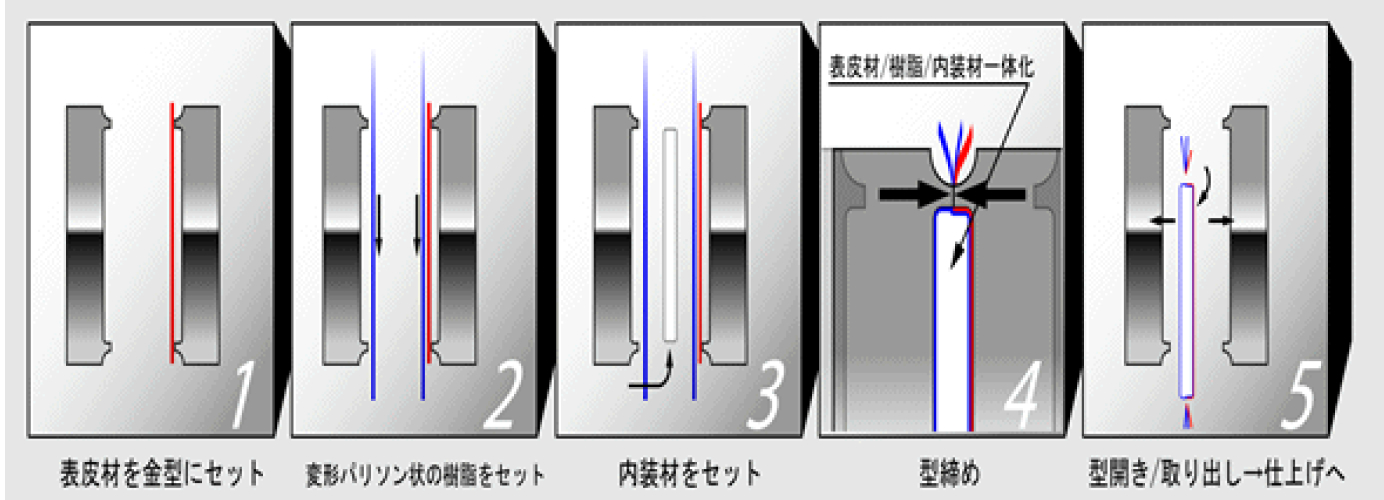

The TBM manufacturing method uses a deformed parison, which was difficult with conventional blow molding.

- Interior material inserts such as foam

- Thickness controlled front and back

- Use of different colors and different materials on the front and back

etc., and we can provide new products that are lighter than blow molding.

Product examples

FLP Lite

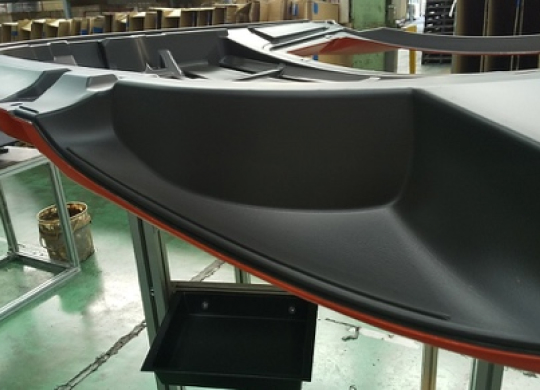

The FLP Lite manufacturing method is a combination of the above TBM and the FLP (non-woven fabric integrated molding) technology that we have cultivated so far.

- Interior material inserts such as foam

- Thickness controlled front and back

- Use of different colors and different materials on the front and back

- Flattening of the back side

etc., and we can provide products with new features that are lighter and more rigid than FLP.

Product examples

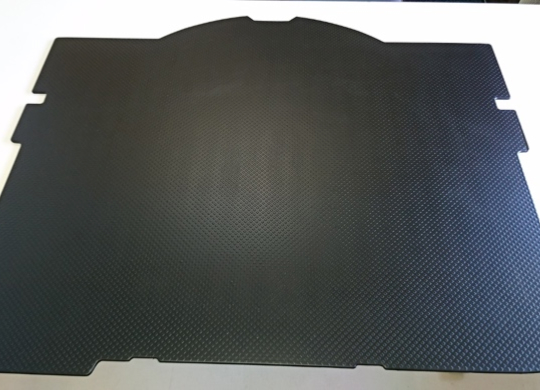

FLP Lite CL

The FLP Lite CL manufacturing method uses a deformed parison to achieve thinning that was difficult with the conventional blow method. Unlike FLP Lite, we do not use inserts for interior materials,

- Hinge integrated molding

- 3D molding

- Small part insert (outsert for aluminum extrusions)

etc., and we can provide products that are lighter than conventional FLP and have new features.

Product examples

Do you have anyworriesorconcerns ?

- I have an idea, but I don't know how to implement it...

- I don't have knowledge or expertise in plastic products...

- Where can i make it

Our company specializes in blow molding, which we have cultivated over many years, and we are working on further developing new molding methods and product development by incorporating our original know-how.

We also have knowledge and experience in other plastic molding methods such as injection molding, extrusion molding, and vacuum pressure molding.

We also handle a wide range of plastic products, such as automobile parts, general molded products, food and medical containers, and films, so we can also accept consultations on manufacturing with plastic.

As a comprehensive plastics company, we provide total support for the manufacturing of our customers by using our facilities and staff to handle all processes from product design to development and mass production.

Inquiries/Consultation

Inquiries/Consultation

For inquiries and consultations

From the form below,

Please feel free to contact us.

We can also meet online.