Injection molding

- Injection molding

- Large molding

- good design

- two-color molding

- Insert molding

What is injection molding

Complicated shapes and designs can easily be reproduced, making it suitable for mass production and the most common molding method for plastic molding.

Advantages of injection molding

Production of quality products

Mold transcription is very expensive, and the design surface is also good.

A wide range of products, from small to large, can be mass-produced

A large number of products can be produced in a short time, and a wide range of product sizes and shapes can be handled.

Less post-processing of molded products

Basically, it can be completed just by cutting the gate part after molding

Technology introduction

Injection molding

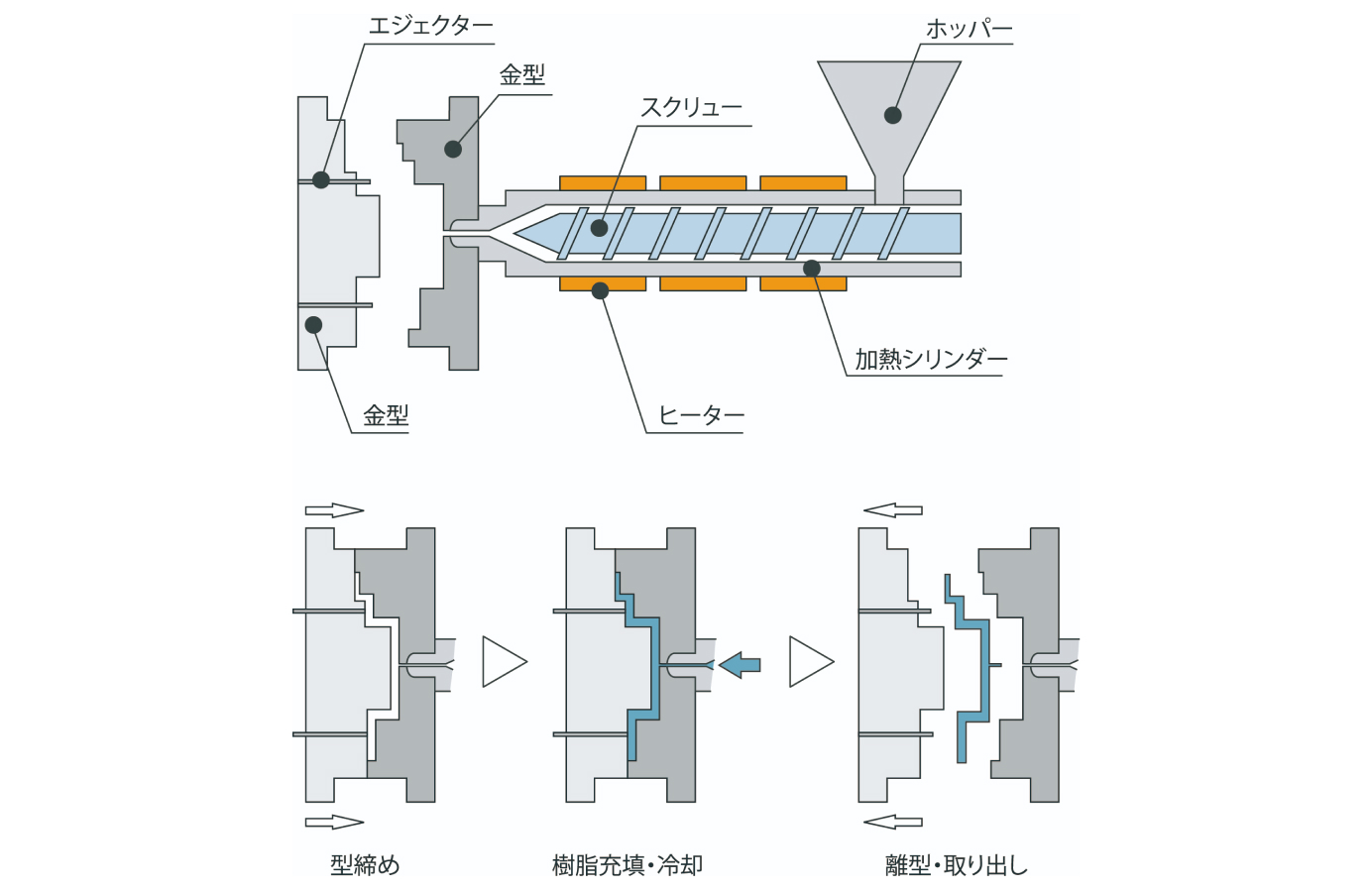

This is a molding method in which resin pellets supplied from a hopper are melted and kneaded in a heating cylinder, filled into a mold with an injection device such as a screw, and after the resin has cooled and solidified, the mold is opened and ejected by an ejector to produce a molded product. . With our original technology, we can also handle two-color molded products with soft materials and large products of 1000 mm or more. Furthermore, we can also support development by pre-simulation such as flow analysis.

Product examples

Do you have anyworriesorconcerns ?

- I have an idea, but I don't know how to implement it...

- I don't have knowledge or expertise in plastic products...

- Where can i make it

Our company specializes in blow molding, which we have cultivated over many years, and we are working on further developing new molding methods and product development by incorporating our original know-how.

We also have knowledge and experience in other plastic molding methods such as injection molding, extrusion molding, and vacuum pressure molding.

We also handle a wide range of plastic products, such as automobile parts, general molded products, food and medical containers, and films, so we can also accept consultations on manufacturing with plastic.

As a comprehensive plastics company, we provide total support for the manufacturing of our customers by using our facilities and staff to handle all processes from product design to development and mass production.

Inquiries/Consultation

Inquiries/Consultation

For inquiries and consultations

From the form below,

Please feel free to contact us.

We can also meet online.