Vacuum forming

- Vacuum forming

- Laminated structure

- Large molding

- Small lot support

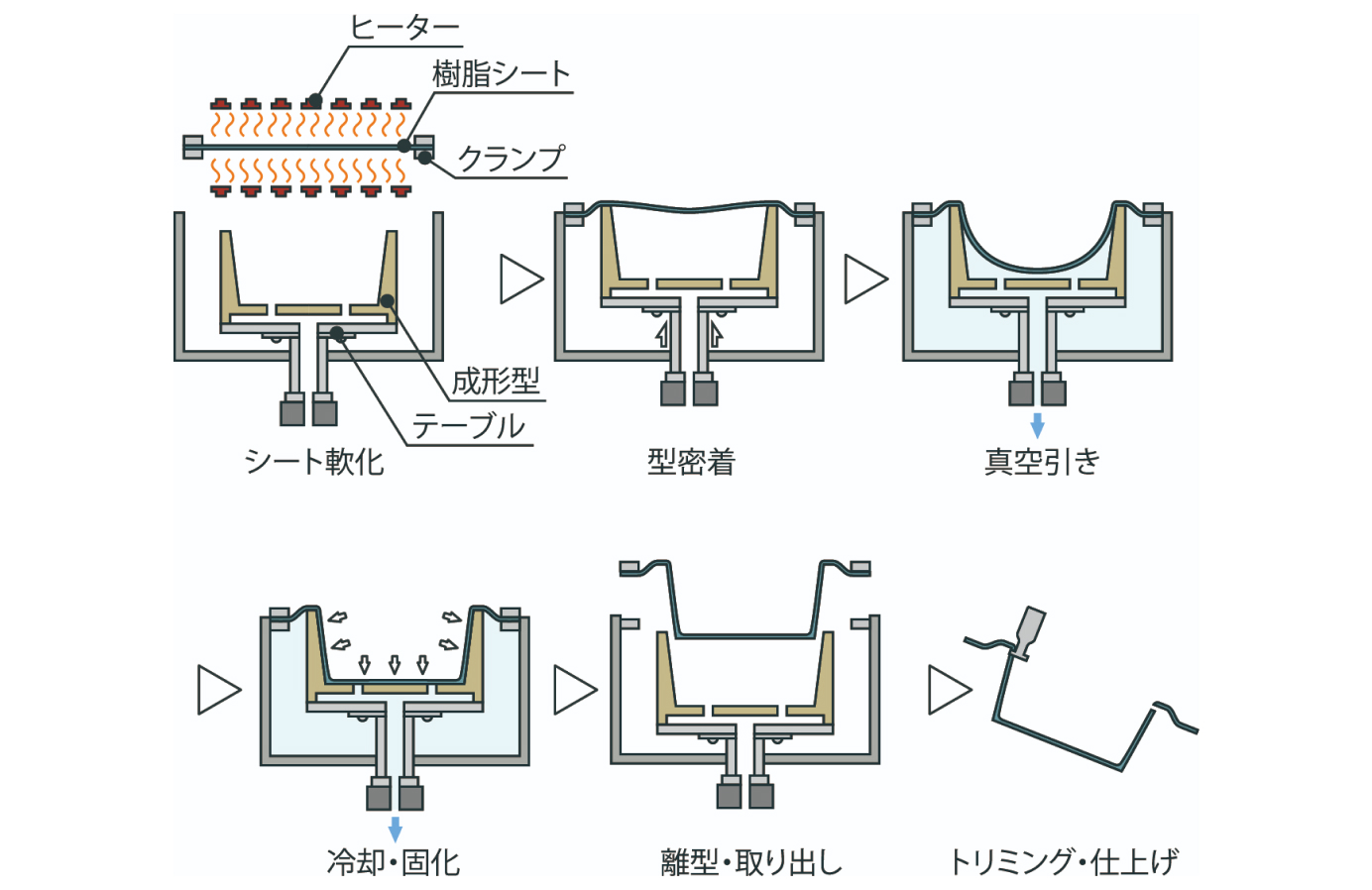

What is vacuum forming

This is a molding method in which a thermoplastic resin sheet is heated and softened, then the sheet is sucked into a molding die and formed into a desired shape.

Advantages of vacuum forming

Low cost of mold/Easy to handle small lot/Short mold production period

Since only one side of the mold is required, the cost of the mold, which accounts for the majority of the initial cost, is reduced, making it easier to handle small lots. It also shortens the mold production period.

Easy to adjust product thickness

The thickness of the product can be freely adjusted by changing the thickness of the sheet.

Technology introduction

Vacuum forming

After heating and softening the thermoplastic resin sheet with a heater, the mold is brought into close contact with the sheet, the air between the mold and the sheet is exhausted with a vacuum pump, and the sheet is formed into the desired shape at atmospheric pressure. increase. After that, it is a molding method that cools and solidifies to obtain the product.

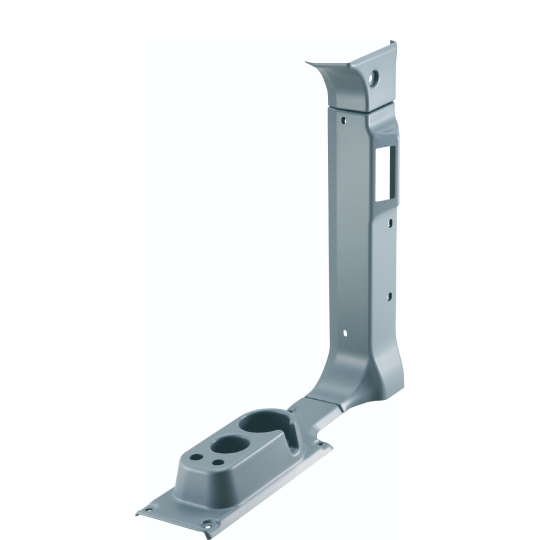

Product examples

Do you have anyworriesorconcerns ?

- I have an idea, but I don't know how to implement it...

- I don't have knowledge or expertise in plastic products...

- Where can i make it

Our company specializes in blow molding, which we have cultivated over many years, and we are working on further developing new molding methods and product development by incorporating our original know-how.

We also have knowledge and experience in other plastic molding methods such as injection molding, extrusion molding, and vacuum pressure molding.

We also handle a wide range of plastic products, such as automobile parts, general molded products, food and medical containers, and films, so we can also accept consultations on manufacturing with plastic.

As a comprehensive plastics company, we provide total support for the manufacturing of our customers by using our facilities and staff to handle all processes from product design to development and mass production.

Inquiries/Consultation

Inquiries/Consultation

For inquiries and consultations

From the form below,

Please feel free to contact us.

We can also meet online.