Interior

- Environmentally friendly

- Weight saving

- two-color molding

- Insert molding

Please contact us if you have any concerns about interior parts such as design and comfort.

We are involved in many interior parts such as floorboard skin in-mold molding and two-color injection molding of different materials. We will respond to the supply of interior parts with our technical strength and know-how.

Product lineup

deck board/floor board

- Material

- PP+TD, PP+GF

- manufacturing method

- FLP Lite

Features

Light weight, high rigidity, in-mold

A board to flatten the luggage compartment

Our company's original technology, FLP Lite, enables molding without skin adhesive material, realization of lightweight and high rigidity by insert molding of core material, and freedom of design and shape by mold molding.

Two-color sheet parts

- Material

- PP+TPO

- manufacturing method

- Two-color injection molding (different materials)

Features

Sealability, environmental friendliness, designability

By adopting two-color molding, we have improved adhesion with different materials and eliminated welding and bonding in the post-process, realizing environmental improvement and designability that does not occur after welding.

Cool box

- Material

- PP

- manufacturing method

- Injection molding + bead foam molding

Features

Thermal insulation, sealing, weight reduction

car refrigerator

Conventionally, urethane was injected into the blow-molded product, but by inserting the foamed beads into the injection-molded product, the adhesiveness of the foamed beads to the heat insulating material can be secured, and the weight can be reduced while maintaining the heat insulation performance. .

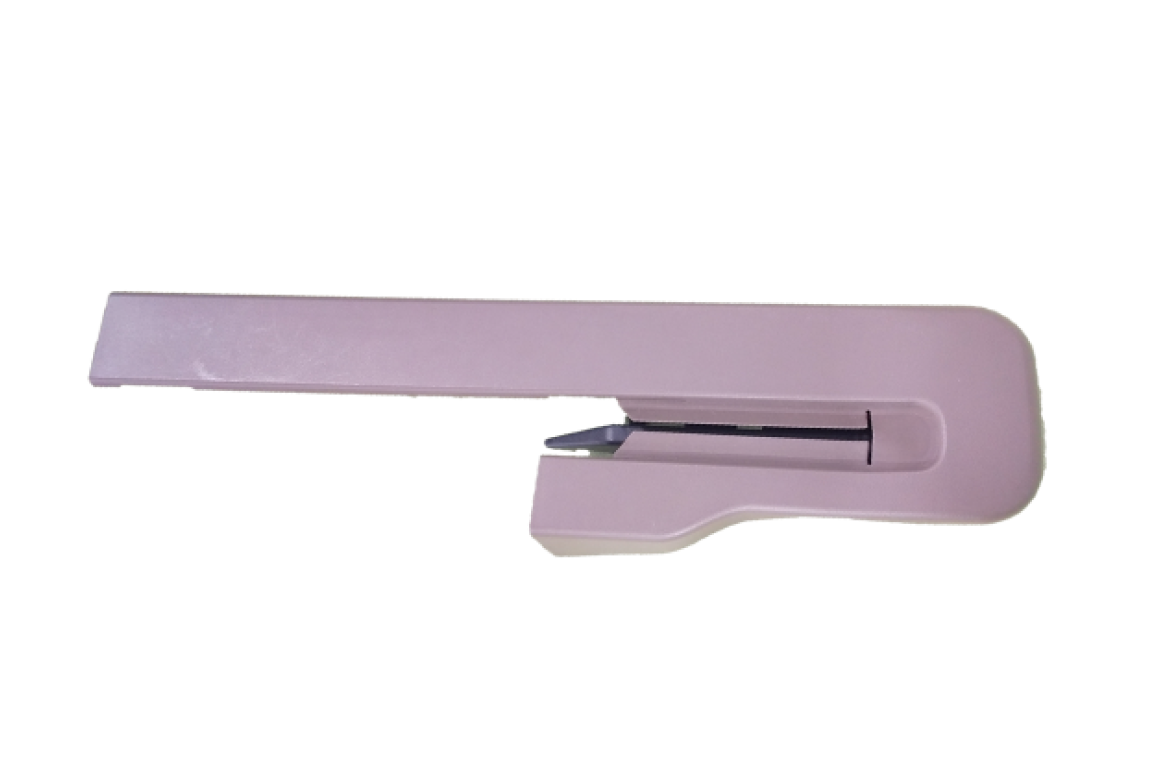

Door pocket

- Material

- PP foam

- manufacturing method

- FSM

Features

Weight reduction, in-mold, mark

Parts attached to the inside of the door pocket

Adhesive-free molding has been realized by in-mold molding the skin on our proprietary FSM technology. Even with the outer skin, the bottle mark can be reproduced, contributing to the improvement of the product appeal.

Flow from inquiry to delivery (⇒ Quotation)

Flow from inquiry to delivery (⇒ Quotation)

- Please contact us with your request using the inquiry form. We also accept consultations at the stage when the requirements are not fixed.

- The person in charge will contact you.

- We will conduct a detailed hearing regarding your request. (Online correspondence is also possible.)

- We will prepare a proposal and estimate.

- If you are satisfied with the contents of the proposal and the estimate, we will carry out the contract procedure.

Quotation/Inquiry/Consultation

Quotation/Inquiry/Consultation

For estimates, inquiries, and consultations

From the form below,

Please feel free to contact us

We can also meet online.