Food containers (seasoning bottles, seasoning tubes)

- maintaining freshness

- sealing

- food

- Blow molding

From single-layer bottles to multi-layer bottles

We manufacture according to customer's request.

Kyoraku has been manufacturing food bottles for over 70 years.

With 70 years of technology, we manufacture easy-to-use food bottles for our customers.

From single-layer bottles to multi-layer bottles, we can meet your needs.

*Please be sure to conduct content, filling, and transportation tests in advance.

Product features

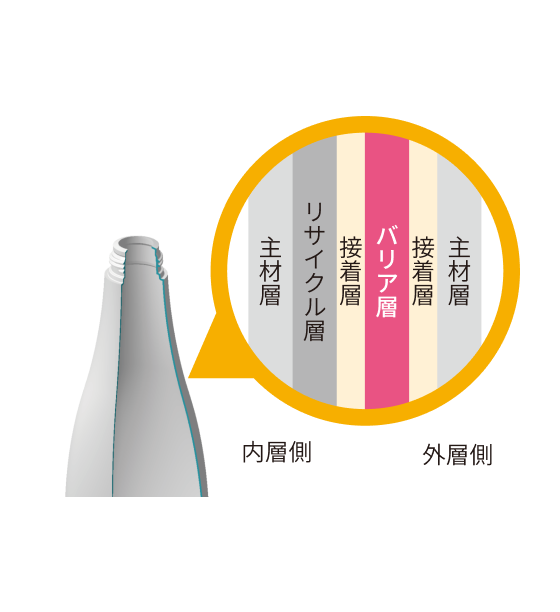

Provides barrier properties with multi-layer structure

The barrier layer that makes it difficult for oxygen and other gases to pass through prevents deterioration of the contents and preserves the aroma and flavor.

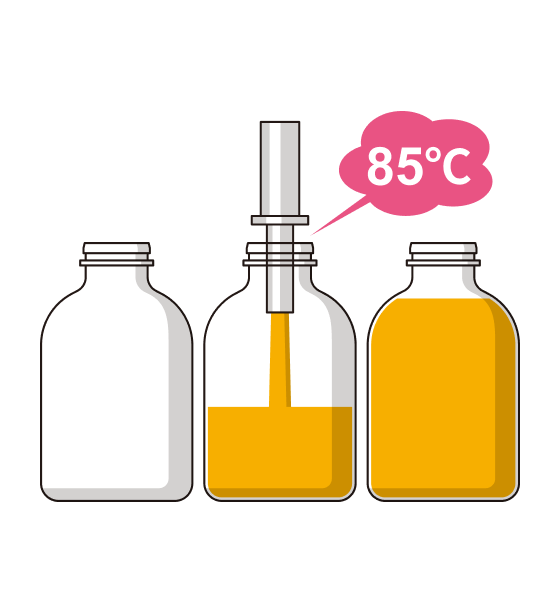

Hot pack possible *MHB series

It is heat resistant and has a track record of filling at 85°C. *The temperature is an actual value, not a guaranteed value. .

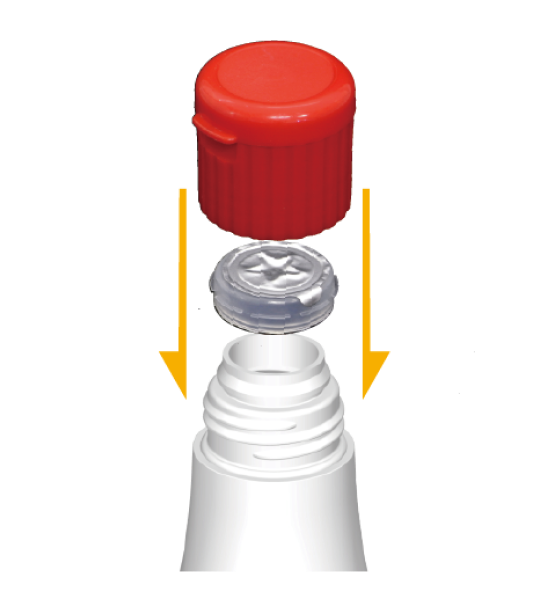

No need for aluminum sealing process *MSB-M series

Since the inner plug with aluminum seal welded is set inside the cap, the inner plug fits into the mouth of the bottle by tightening the cap after filling.

Delivery possible from 1 case

Bottles of all series can be delivered from 1 case.

Product lineup

Seasoning Bottle/Seasoning Tube (Type with Inner Plug)

MSB-M Polyethylene multilayer soft bottle with inner plug type

Usage

Mayonnaise bottles, wasabi tubes, mustard tubes, chocolate sauce bottles, fruit sauce bottles, tartar sauce bottles, brown sugar syrup bottles, oligosaccharide bottles, honey bottles, etc.

A bottle with polyethylene as the main material layer, which is characterized by its squeezability (easiness of squeezing).

It has an EVOH layer (barrier layer) to provide gas barrier properties, oil resistance, organic solvent resistance, and fragrance retention.

Due to the features of our standard cap, it can be used simply by tightening the cap after filling. (No need for aluminum seal welding process)

|

|

|

|

| capacity | 226ml | 328ml | 548ml |

|---|---|---|---|

| Height x body width | 166×60×48 | 188×70×51 | 220×83×61 |

| Quantity | 400/cs | 300/cs | 160 lines/cs |

| Material | LDPEmultilayer | ||

| Mouth specifications | Inner plug with aluminum seal + screw type | ||

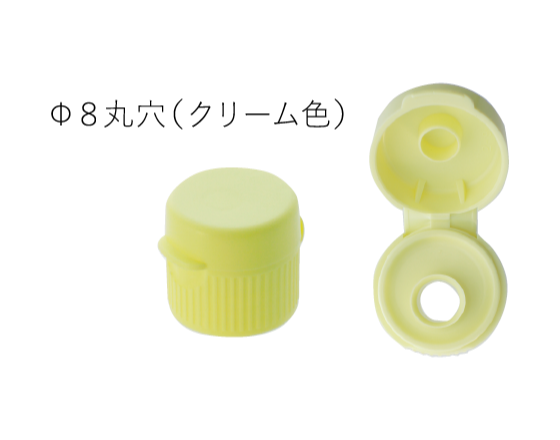

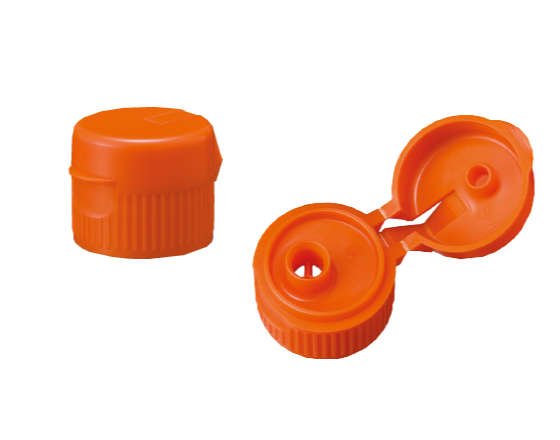

Cap for MSB-M series (M squeeze hinge cap)

|

||

| Quantity | 1500 pieces/cs | |

|---|---|---|

Seasoning Bottle/Seasoning Tube (Aluminum Seal Type)

MSB polyethylene multilayer soft bottle aluminum seal type

Usage

Wasabi tube, mustard tube, chocolate sauce bottle, fruit sauce bottle, jam bottle, paste bottle, grated ginger tube, grated garlic tube, grated maple leaf tube, pizza sauce bottle, mentaiko bottle, miso bottle, vinegar miso bottle, cream cheese bottle, etc.

It can be used for various purposes depending on the variation of the spout of the cap. Weld the aluminum seal after filling.

|

|

|

|

| capacity | 123ml | 187ml | 276ml |

|---|---|---|---|

| Height x body width | 126×52×36 | 150×59×44 | 166×60×47 |

| Quantity | 420 lines/cs | 380 lines/cs | 400/cs |

| Material | LDPEmultilayer | ||

| Mouth specifications | Aluminum seal + screw type | ||

Cap for MSB series (K squeeze hinge cap)

|

|

||

| Quantity | 3000pcs/cs | ||

|---|---|---|---|

heat resistant seasoning bottle

MHB series (hard bottle type)

Usage

Yakiniku sauce bottle, noodle soup bottle, cooking oil bottle, sauce bottle, dressing bottle, etc.

This bottle is mainly made of polypropylene, which is rigid and heat-resistant and can be hot-packed.

The cap can be selected from a stopper type and a screw type depending on the application.

|

|

|

|

|

|

| capacity | 450ml | 223.5ml | 1035ml | 1551ml | 1870ml |

|---|---|---|---|---|---|

| Height x body width | 197×80×50 | 123×73×44 | 255×Φ83 | 265 x Φ108 | 305 x Φ108 |

| Quantity | 112 lines/cs | 240 lines/cs | 70 lines/cs | 50/cs | 50/cs |

| Material | PP multilayer | PP multilayer | PP multilayer | HDPEmultilayer | HDPEmultilayer |

| Mouth specifications | screw type | Plugging type | Plugging type | Plugging type | Plugging type |

Cap for MHB series

Φ6Y hole (screw) |

|

|

|

| Quantity | 3000pcs/cs | 2000 pieces/cs | 2000 pieces/cs |

|---|

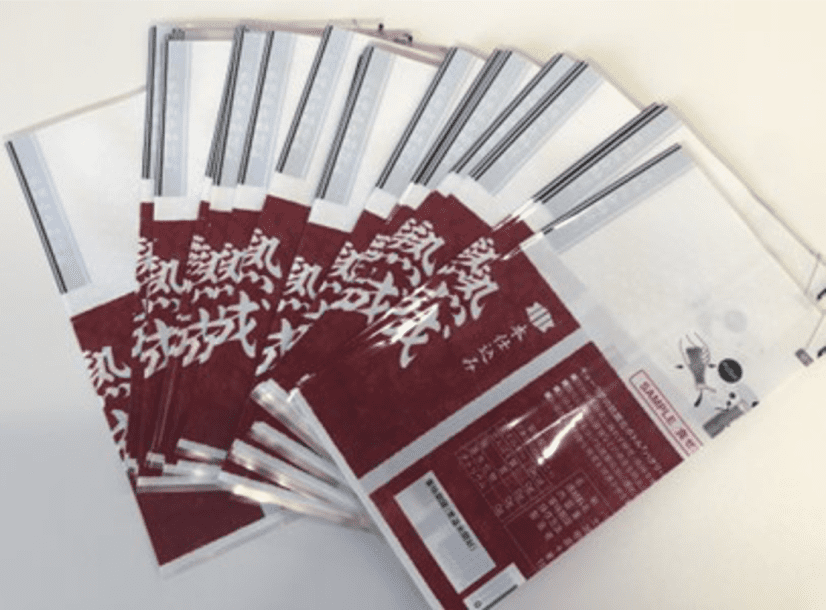

Proposal for shrink labels

We propose shrink labels for food containers and cosmetic containers, including designs.

Proposal flow

-

Selection of shrink printing method

- Gavure printing

・Printing method using plates

・Plate fee is required for each color

・Rampage period is 1 year to 1.5 years (printing period of 2 years is also possible)

・Printing in ideal colors is possible (gold, silver, matte, special colors)

・There is a unit price advantage in the order cycle with economic lots

- Digital printing

・Printing method that does not use a plate (No plate fee is required)

・Price per sheet is higher than gravure printing

・Economic lot (e.g. 10,000 sheets) can be printed with multiple items

(Example: 2,000 sheets x 5 products)

・Printing with multiplication (printing with gold, silver, special color is not possible)

- Gavure printing

-

Design meeting

It is also possible to introduce a designer and create a design.

If you have a design base such as a paper label, you can also create a design that matches the bottle used at Kyoraku.

-

Create a shrink sample

Shrink the design of the block copy to the actual bottle, the positional relationship of the design,

Check the perforation position.

Left: This product / Right: Shrink sample

Shrink samples will appear lighter in color. It is not a color swatch.

-

The front design and back design are confirmed by the customer again, and printing starts after proofreading.

Proposal for bottle filling machine

We offer a total solution for filling machines for food and cosmetics, from bottle alignment machines to packaging.

We manufacture custom-made manual filling lines, semi-automatic filling lines, and fully automatic filling lines according to the customer's layout space and filling speed.

Quotation/Inquiry/Consultation

Quotation/Inquiry/Consultation

For estimates, inquiries, and consultations

From the form below,

Please feel free to contact us

We can also meet online.